DTF Printing

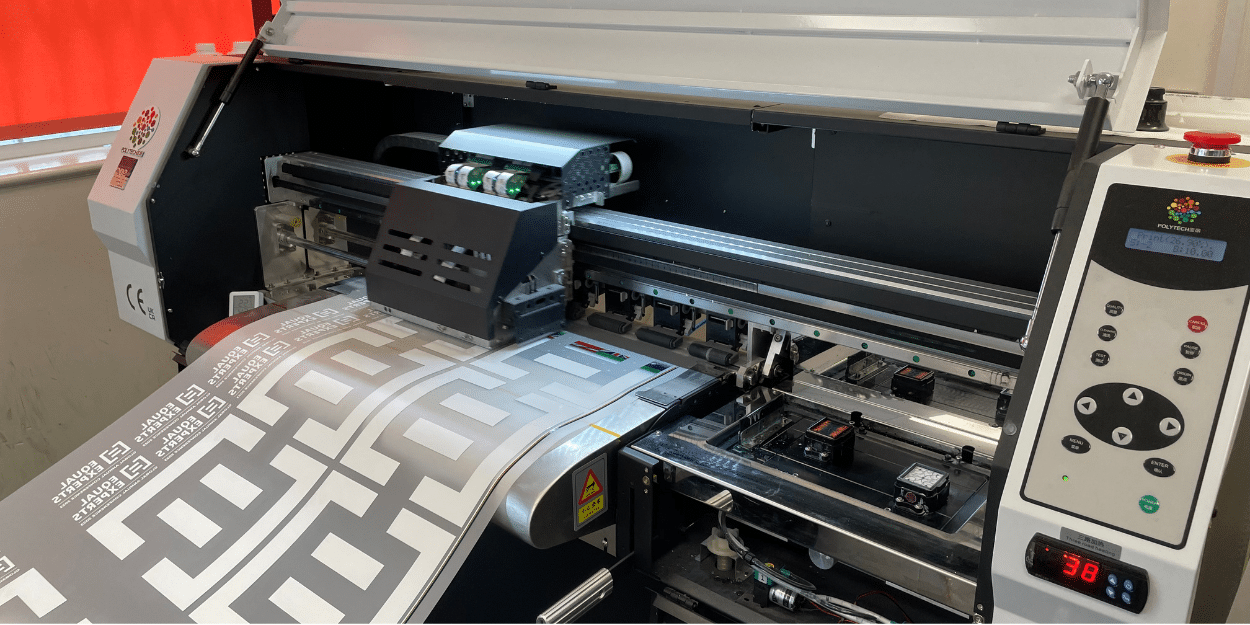

Direct-To-Film (DTF) Printing involves printing a design onto a piece of PET film (a special film with a coating that helps transfer designs). The design on the film is then heat transferred onto a garment using a heat press machine.

This method of printing uses water-based transfers creating a more sustainable way of garment decoration.

Benefits of DTF Printing

High-Quality Results

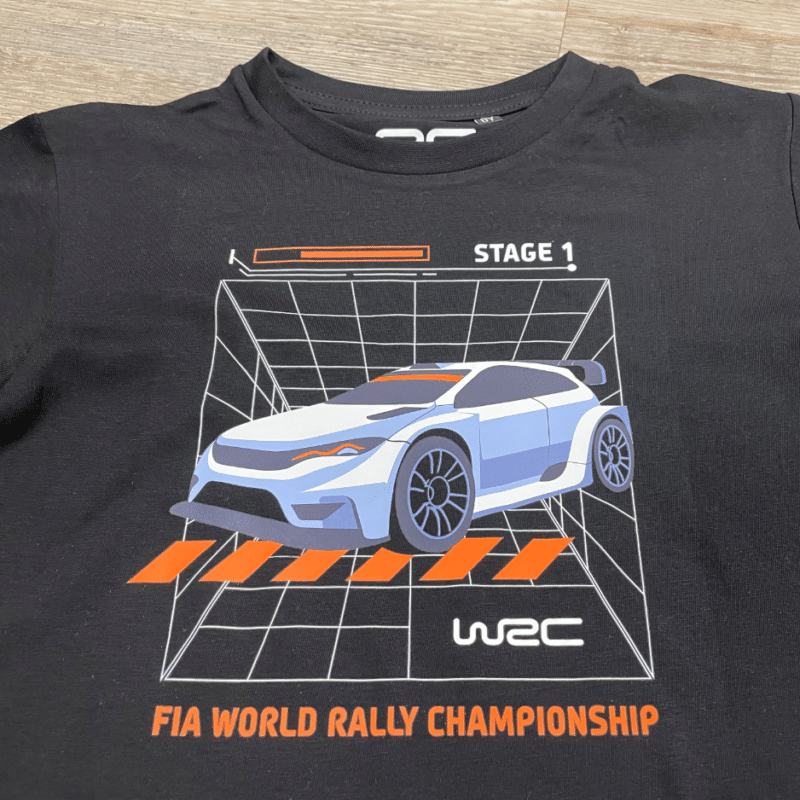

Direct-To-Film printing enables intricate designs and sharp details with vibrant colours and a soft hand feel.

Versatility

DTF printing can be used on a variety of products such as t-shirts, hoodies, bags, caps and more.

Speed and Efficiency

This process has a much quicker set up process making it great for smaller orders with lots of colours, compared to screen printing.

Flexible and Comfortable

Compared to the old plastic transfer prints, DTF prints have a soft hand feel and are flexible, making it comfortable for the wearer.